This is an old revision of the document!

Lulzbot Taz4

3D Drucker der derzeit im Raum ist und super cool und verwendbar: Lulzbot TAZ4

Manual

Tipps and Caveats

Heatbed too cold

Does it affect your print? If not, don't worry about it. Otherwise see below.

On cold days the heatbed glass can lag about 10min behind the heatbed temperature. Close the window curtain to reduce ambient heat loss. Preheating the bed for a longer time before starting the print may help. If the heatbed continously does not reach target temperature, use the materials in MaSha to build an enclosure for the TAZ.

Filament gets stuck, print stops

There is an edge inside the extruder in the filament shaft between the metal and plastic part. It can't be fixed, but the filament can be inserted in a way that the natural curl of the filament keeps the filament from getting stuck on that edge.

Use the PTFE tube to guide the filament into the extruder from the backside (display is front-side) of the printer.

We observed Stainless-Steel PLA to be wobbly on some places on the spool. The wobbles will make the filament get stuck in the PTFE tube. Try without the tube. Watch the print and make sure filament does not get stuck.

Some parts of my design is not being printed

- Check your model in the layer view of Cura.

- Wall thickness should be a multiple of the nozzle size.

- Try a finer profile.

Extruder or other stepper overheats and stops working

This happened once, because the current regulation on the controller board was shot. Read the blog. Order new board and replace it.

Model Design

You wall thickness should be a multiple of the nozzle size.

If you are printing thing walls for cookie cutters, make sure your wall is thick enough to be printed. You can check in cura in the layers-view.

Materials

Correct profiles for each material can be found in: ~/lulzbot/cura profiles/

Fast Profile is alsmost always the right choice, unless you intend to print small models with very fine structures.

Use Cleaning Filament when changing to a filament with a different extrusion temperature.

Otherwise lower-temp filament will charcoal inside the hotend at higher temperatures which can obsctruct the hot-end and create back-pressure and can be almost impossible to clean out.

currently in realraum

-

- Spool Length: ~140m

- normal price

- nice material strength

- warps on large surface area

- needs raft for less than 4cm² ground surface

-

- Spool Length: 62.7m

- normal price

- awesome material durability and strength

- needs glue and no printbed heat to stick. even so has tendency of getting loose

-

- Spool Length: 56m

- more expensive, double price

- translucent

- brittle

-

- Spool Length: 56m

- more expensive, double price

- translucent

- brittle

-

- Spool Length: ~125m

- normal price

-

- Spool Length: ~30m

- really expensive, 5 times usual price.

actually more than 10 times as expensive as HIPS per meter. - brittle on small features but durable like PLA and heavy on bigger pieces

- sticks really well on printbed. do not use glue or can forget about getting your print off the bed

-

- Spool Length: ~5m

- use only for cleaning and when changing filaments

-

- Spool Length 750g: ~95m

- Spool Length 2200g: 270m

- only slightly more expensive

- supposedly least warping so good for precise prints

- supposedly sticks on printbed really well on its own

See the Lulzbot Filament Guide on print-settings for various materials.

See also the Lulzbot Cura Profiles Page

Printing with Nylon

Nylon does not stick to the print-bed. Not even with the heat turned on.

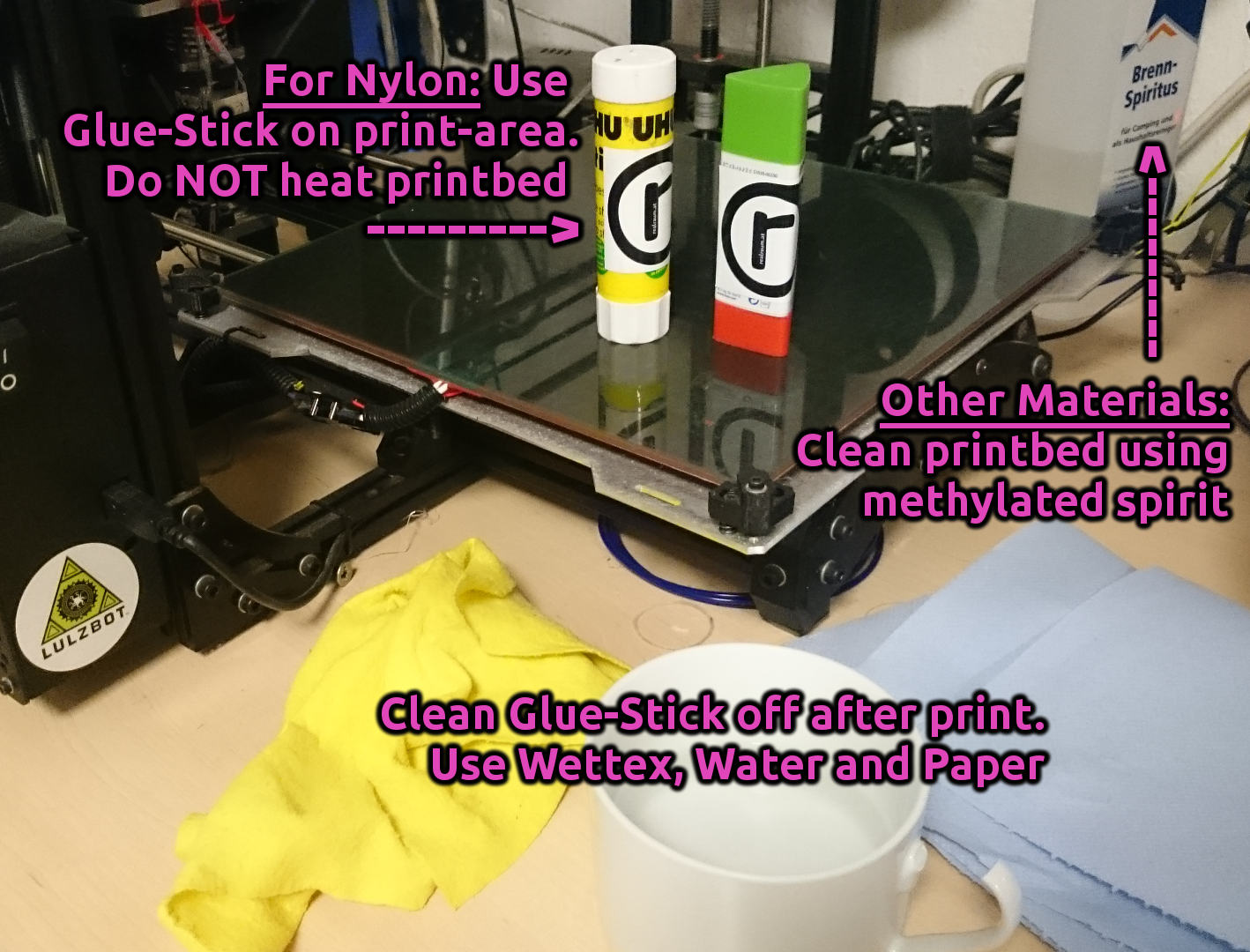

- Use Glue-Stick on printbed beforehand. Glue-Stick is in black LulzBot Bag, Please store there again after use.

Do NOT heat the printbed. That just leads to the Glue drying out early and the print failing.

you can heat the printbed normally. With the new PET surface, Bridge Nylon steaks really well on a heated and glued printbed.- Glue-Stick-glue is water-solvable. Clean printbed by putting wet paper or wet wettex on it, let it soak a minute and whipe off with paper afterwards!. Repeat several times until print-bed completely clean.

Nylon should regularly dried at 80°C for 7 Hours and stored in airtight container with desiccant. (Under the Table)

Printing with Stainless Steel PLA

Stainless Steel PLA sticks REALLY well to the PET surface. Don't use glue.

When the print is finished, wait for the pad cools and then VERY carefully try not to damage the print surface!

what can be printed ?

Everything with a filament diameter of 3mm (no less and no more) and extrusion temperature below 238°C that does not clog 0.35mm nozzles, like wood-,stainless-steel-,conducitve,“magnetic”-filament does.

about 1.75mm filament

To print 1.75mm filament, a different PTFE-Tube would be needed. However, Lulzbot no longer manufactures or sells them. Conceivably they are easy to make yourself from aluminum or PTFE with a lathe. Seeing as their newest Hexagon Hotend does not even mention the option of printing anything but 3mm filament, Lulzbot seems to have completely abandoned support for anything other than 3mm filament.

Quote from Lulzbot-Sales 2015-09-25:

I do apologize, but we no longer carry those tubes. We have tested several filaments on our printers, and prefer the 3 mm size, as it much easier to work with.

Specs and Settings

| Specs TAZ 4.1 – Test Acceptance Record | |

|---|---|

| max build Area | 298mm x 275mm x 250mm |

| Resolution: | >=0.1mm |

| max Heatbed Temp | 120°C |

| max build speed | 200mm/s |

| Firmware | Marlin 2014-Q3 |

| Electronics | RAMBo 1.3L |

| Serial# | KT-PR0016-7986 |

| steps/mm X | 100.5 |

| steps/mm Y | 100.5 |

| steps/mm Z | 400 |

| steps/mm E0 | 842 |

Nozzle

| currently mounted Nozzle | |

|---|---|

| Diameter | 0.35mm |

| Max Temperature | 240°C (exceed at risk of DAMAGE) |

| Type | Budaschnozzle 2.0c |

Current Firmware Settings

2015-11-12

| Value | Setting from LCD |

|---|---|

| Autotemp | Off |

| Autotemp Min | 210 |

| Autotemp Max | 250 |

| Autotemp Fact | 0.10 |

| PID-P | 6.00 |

| PID-I | 0.30 |

| PID-D | 125.00 |

| PID-C | 1 |

| Zoffset | 0 |

| Accel | 500 |

| Vxy-jerk | 8 |

| vz-jerk | 0.40 |

| ve-jerk | 10 |

| vmax x | 800 |

| vmax y | 800 |

| vmax z | 8 |

| vmax e | 50 |

| amax x | 9000 |

| amax y | 9000 |

| amax z | 100 |

| amax e | 10000 |

| a-retract | 3000 |

| xsteps/mm | 100.50 |

| ysteps/mm | 100.50 |

| zsteps/mm | 1600 |

| Esteps/mm | 842.0 |

| E1steps/mm | 800.00 |

HeatBed Autotune

2015-11-12

bias: 41 d: 41 min: 64.86 max: 65.28 Ku: 250.58 Tu: 18.09 Clasic PID Kp: 150.35 Ki: 16.62 Kd: 339.93 PID Autotune finished! Put the Kp, Ki and Kd constants into Configuration.h